September 22, 2023

Empowering High Performance Water-based Leather Coating Products | Technical Control Waterborne Polyurethane Resin for Leather Coating

The purpose of leather coating is to improve the appearance of tanned leather, to cover and correct the original or defects caused by previous improper processing. And finally to impart the leather with good physical performance and appearance according to the needs of customers and the market.

Common leather finishing processes include filling, base coating, intermediate coating and top coating. According to the finishing requirements of each coating, Technical Control designs and has developed a series of waterborne polyurethane resins suitable for leather finishing. Leather coating manufacturers can find environmentally friendly chemical raw materials for diversified high-performance finishing coatings. All leather finishing solutions comply with the Zero Discharge of Hazardous Chemicals (ZDHC) Manufacturing Restricted Substances List (MRSL).

The base coat is featured with high coverage to make the surface of the crust leather uniform. At the same time, as a bridge between the crust leather and the effect coating, base coat is required to have strong adhesion. Choosing the right polymer is particularly important.

Intermediate Coating can be either transparent or opaque, provides a certain hardness to the coating, and some physical and mechanical operations, including ironing and embossing, before applying the top coating. The hardness of the coating layer gradually increases from bottom to top.

The top coat of leather is a waterborne polymer which is slightly harder than the previous coats. The top coats can meet the physical and chemical resistance properties according to the application, giving the leather a better touch and aesthetics.

Common leather finishing processes include filling, base coating, intermediate coating and top coating. According to the finishing requirements of each coating, Technical Control designs and has developed a series of waterborne polyurethane resins suitable for leather finishing. Leather coating manufacturers can find environmentally friendly chemical raw materials for diversified high-performance finishing coatings. All leather finishing solutions comply with the Zero Discharge of Hazardous Chemicals (ZDHC) Manufacturing Restricted Substances List (MRSL).

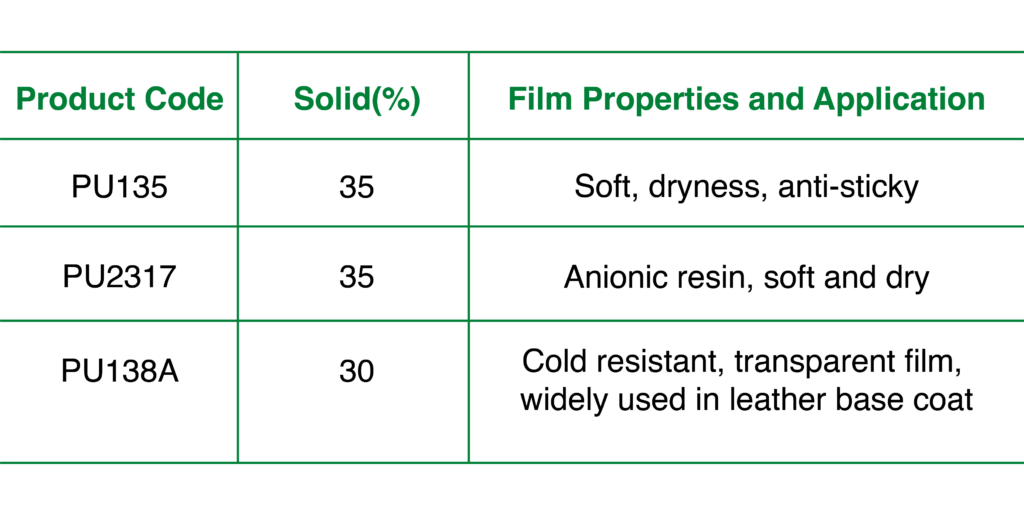

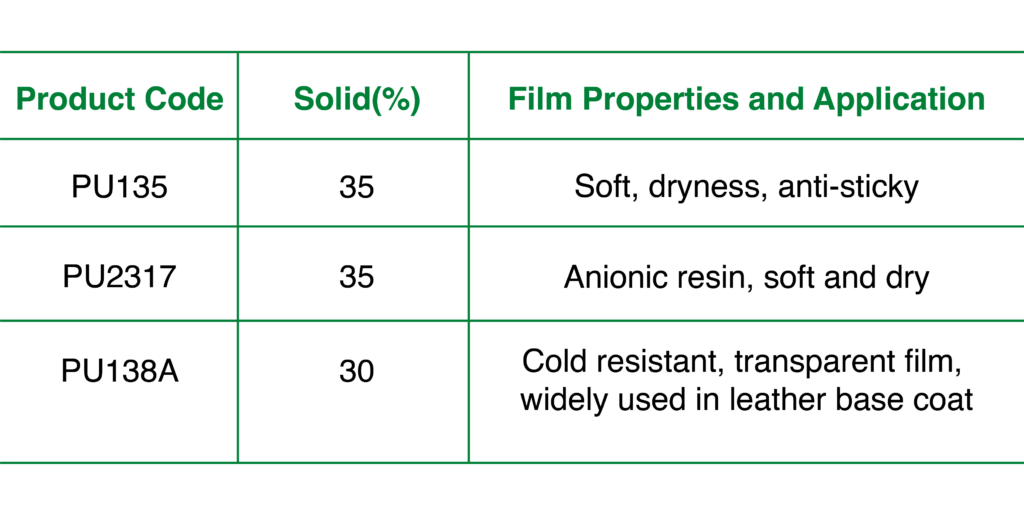

Base Coat

The base coat is featured with high coverage to make the surface of the crust leather uniform. At the same time, as a bridge between the crust leather and the effect coating, base coat is required to have strong adhesion. Choosing the right polymer is particularly important.

Waterborne PUD for the Formulation of Base Coat

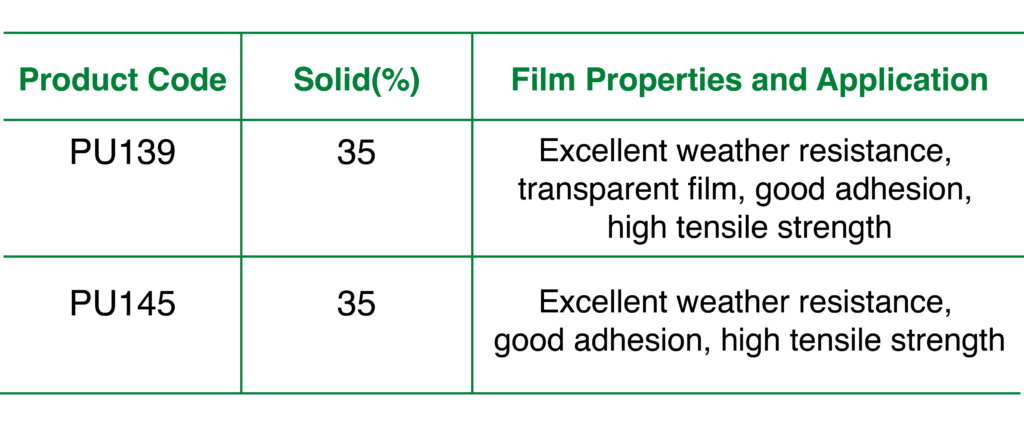

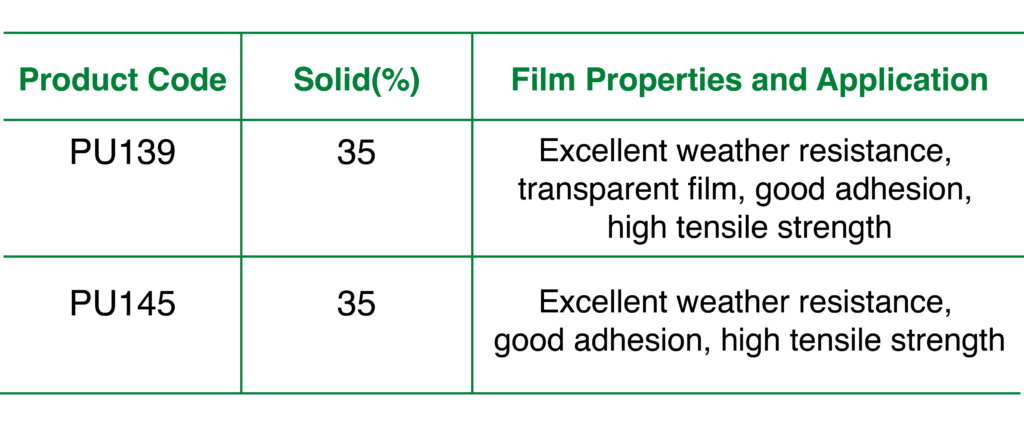

Intermediate Coat

Intermediate Coating can be either transparent or opaque, provides a certain hardness to the coating, and some physical and mechanical operations, including ironing and embossing, before applying the top coating. The hardness of the coating layer gradually increases from bottom to top.

Waterborne PUD for the Formulation of Intermediate Coat

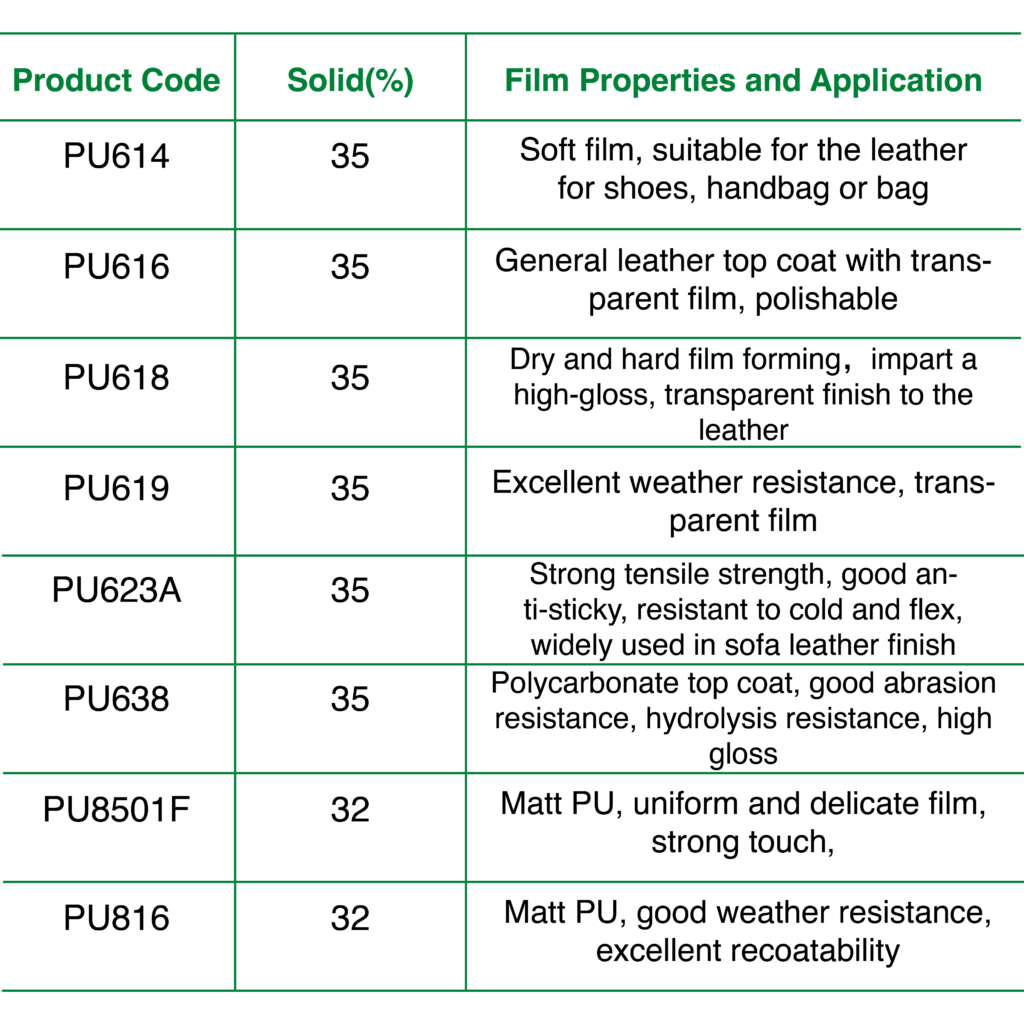

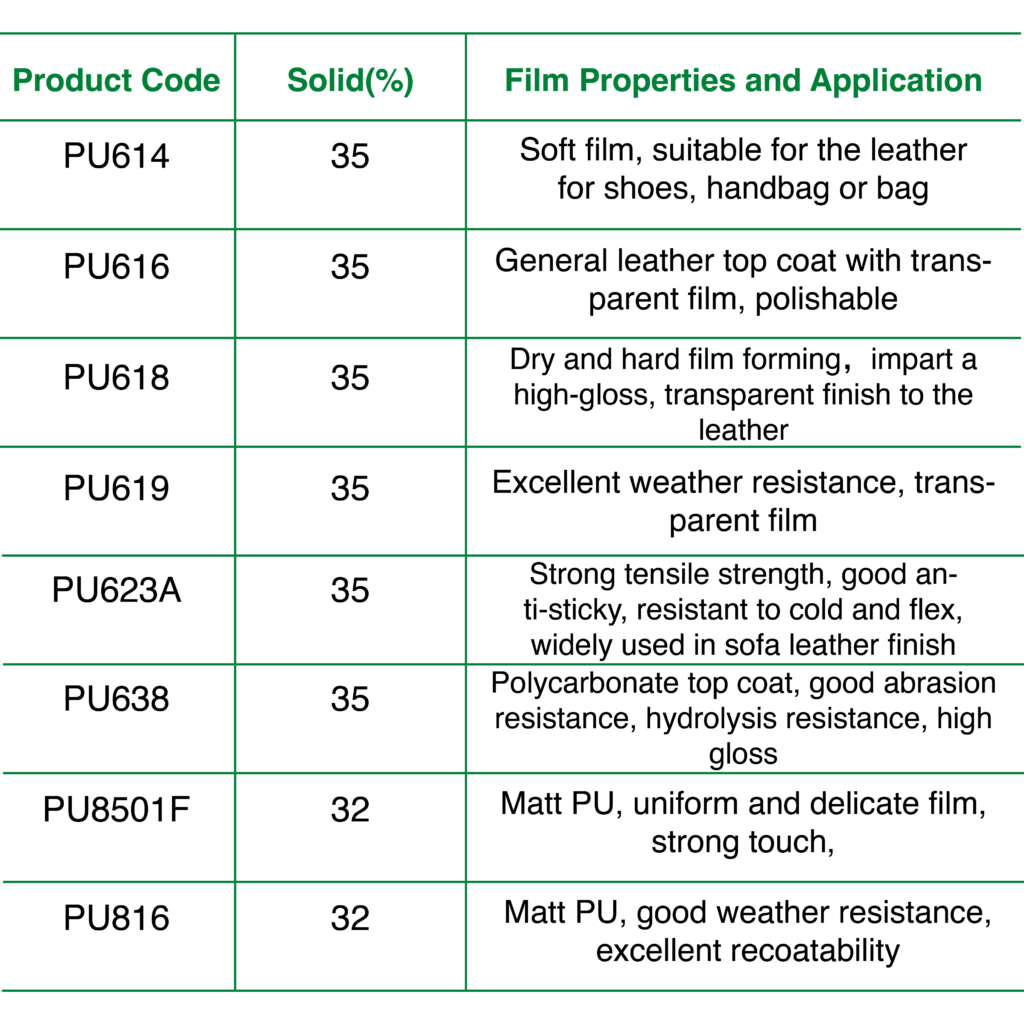

Top Coat

The top coat of leather is a waterborne polymer which is slightly harder than the previous coats. The top coats can meet the physical and chemical resistance properties according to the application, giving the leather a better touch and aesthetics.

Waterborne PUD for the Formulation of Top Coat